[最も人気のある!] aluminum 6061-t6 properties 569053-Welded 6061-t6 aluminum properties

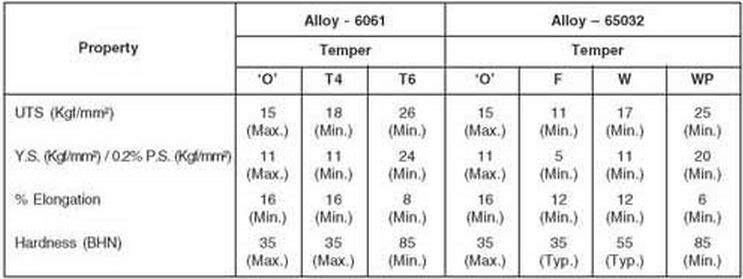

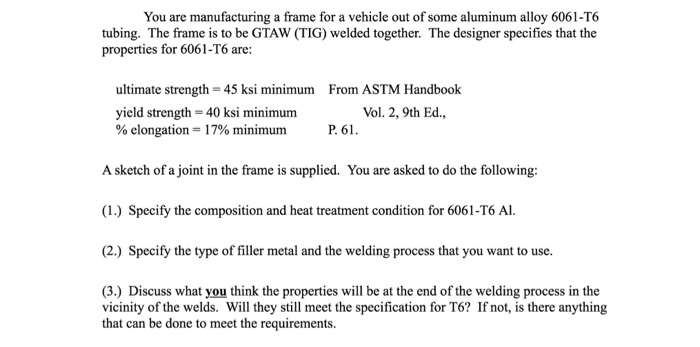

When choosing between two particular alloys, it is important to fully compare their unique properties 24 is among the more popular high strength aluminum alloys It is recognized for its strength and fatigue resistance and offers a good strengthtoweight ratioMar 14, 11 · There is no doubt that the result will be 6061T6 properties if you do it properly The main difficulty is that the component usually distorts quite a bit during quenching and requires significant mechanical straightening before aging This is often very difficult or even impossible, especially on large weldments10 mm ball Hardness, Knoop 1 1 Converted

Http Www Allianceorg Com Pdfs Alumext 6061t6 Pdf

Welded 6061-t6 aluminum properties

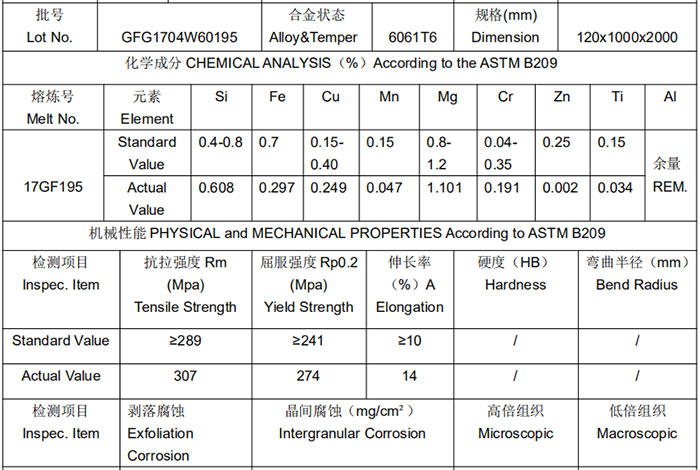

Welded 6061-t6 aluminum properties-Typical Electrical Properties Metric English Comments Electrical Resistivity ohmcm @Temperature 0 °C ohmcm @Temperature 680 °F AA;Aug 01, · The mechanical properties of aluminum depends mainly on its temper or heat treatment procedure It is commonly available in pretempered grade such as 6061O (annealed), 6061T4 and 6061T6 grades The Young's modulus 6 GPa of these grades are the same but the tensile strength and yield strength are greatly different

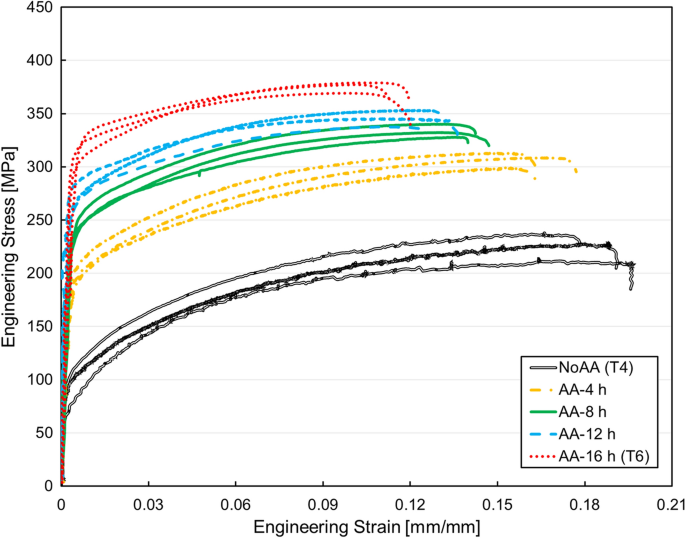

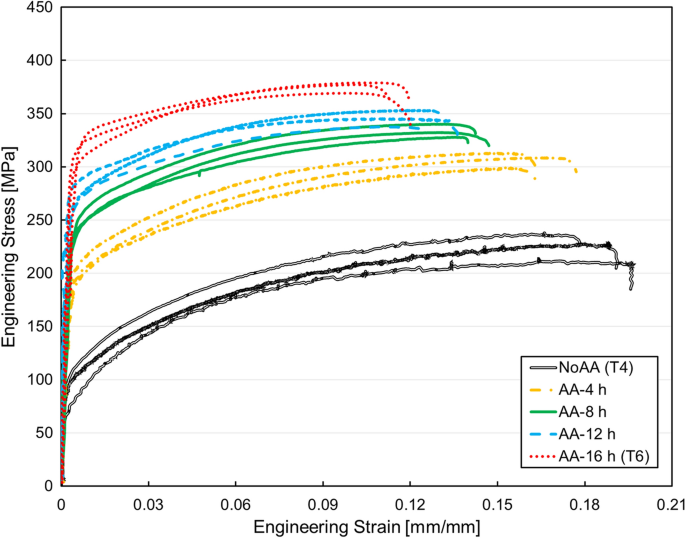

Stress Strain Properties Of Artificially Aged 6061 Al Alloy Experiments And Modeling Springerlink

6061 is the least expensive and most versatile of the heattreatable aluminum alloys It has most of the good qualities of aluminum It offers a range of good mechanical properties and good corrosion resistance It can be fabricated by most of the commonly used techniques6061T6 aluminum properties include its structural strength and toughness It is also offers good finishing characteristics and responds well to anodizing, including clear, clear and color dye, and hardcoat 6061 aluminum alloy is also easily welded and joined6061T6 Aluminum association wide flange beam is an excellent candidate for most processing techniques and both interior and exterior applications Aluminum American standard wide flange beams have a smooth finish and a tapered flange against the web meeting the specifications for AMSQQA 0 Common applications include buildings, walkways

Machinability 50 % 50 % 0100 Scale of Aluminum Alloys Shear Modulus 260 GPa 3770 ksi Estimated from similar Al alloys Shear Strength 7 MPa psi AA;6061 Aluminum Bar Stock 6061 (UNS 6061) is an aluminum bar with cold finished or extruded aluminum wrought product with excellent corrosion resistance, good workability, fabulous joining characteristics and adequate machinability 6061 is one of the most widely used heat treatable aluminum alloys It has excellent corrosion resistance, good1 4 equation of the form y = a bT cT 2 dT 3 eT 4 >T > Tlow y = f T < Tlow solves as expected Where Coefficients ae are summarized in the appropriate table and T is the temperature in K (xaxis), and y is the property to solve for See References

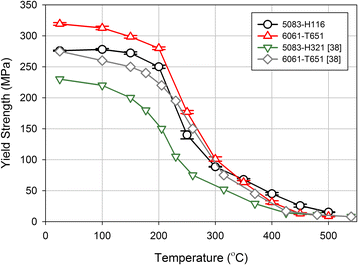

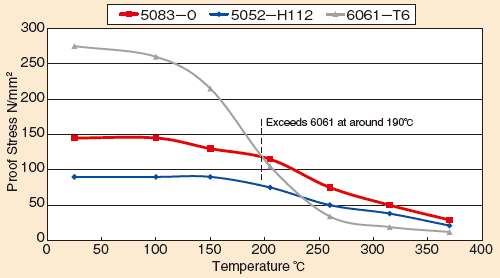

Mechanical properties of aluminum alloys tensile strength, yield strength and more Aluminum alloys are divided into the wrought and cast categories according to how they are produced The wrought category includes rolling, extruding, drawing, forging, and a number of other more specialized processes Cast alloys are poured molten into sand (sand casting) or highstrengthOct 25, 17 · Aluminium 6061T6 Properties and Data Tables When compared to other 6061 alloy types that have been introduced to a different tempering procedure, the T6 boasts slightly better machinability characteristics as well as slightly improved anodizing response, but is also characterised by a lower level of formability Its corrosion resistance properties, weldability, andJun 02, 21 · equation of the form y = a bT cT 2 dT 3 eT 4 >T > T low y = f T < T low solves as expected Where Coefficients ae are summarized in the appropriate table and T is the temperature in K (xaxis), and y is the property to solve for Young's Modulus of

6061 T6 Aluminum Yield Stress Search For A Good Cause

Which Aluminum Alloy Bends Best Clinton Aluminum

6061 aluminium alloy Wikipedia, the freeWidely available The T8 and T9 tempers offer better chipping characteristics over the T6 temperDec 23, · Aluminum 6061T6 Properties and Applications Aluminum 6061T6 is a type of precipitationhardened aluminum alloy that has been treated Precipitation hardening applies high temperatures to reduce its plasticity and increase the yield strength

Material Properties Of Aluminum Alloy 6061 T6 Alumina And Steel Download Table

Aluminum Workshop Is It Possible To Restore Tensile Strength In Welded 6061 T6

6061T651 Subcategory 6000 Series Aluminum Alloy;Jun 06, 21 · 6061 t4 Aluminum Sheet 6061 t4 aluminum is famous for its higher formability than t6 And 6061 t4 aluminum sheet can accomplish fairly severe forming operations, due to its higher elongation percentage Besides, the 6061 t4 properties (mechanical strength) are higher than 6061O, but far less than 6061T6 alloyMaterial properties Aluminum 6061T6 Get in touch EU 44 3966 98 or US 1 or at sales@hubscom wwwhubscom (v100, 19) Heat treatments for CNC machined parts Learn how heat treatments can be applied to many metal alloys to drastically improve key physical properties like hardness, strength and machinability

6061 Aluminum Get To Know Its Properties And Uses Gabrian

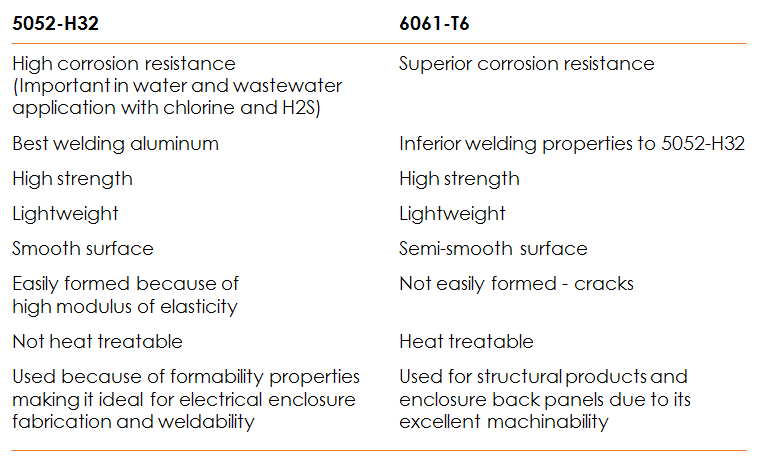

5052 Vs 6061 Aluminum Properties Yield Strength Differences Of 5052 H32 Vs 6061 T6 Nema Enclosures

Seamless Aluminum Pipe Series 6061T6 Schedule 40 6061 is the least expensive and most versatile of the heattreatable aluminum alloys It has most of the good qualities of aluminum It offers a range of good mechanical properties and good corrosion resistance It can be fabricated by most of the commonly used techniquesInformation provided by Alcoa, Starmet and the references General 6061 characteristics and uses Excellent joining characteristics, good acceptance of applied coatings Combines relatively high strength, good workability, and high resistance to corrosion;6061T6 aluminum pipe is extruded meaning it is seamless and an excellent candidate interior and exterior applications It is good for most processing techniques, although not recommended for bending or forming Common applications include railings, docks, posts, and hinges It's lightweight with a smooth light grey finish

When And Why To Use Aluminum 6061 Ryerson

Iopscience Iop Org Article 10 10 1742 6596 1198 3 0302 Pdf

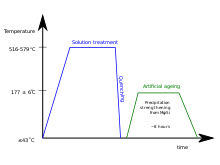

May 30, · 6061T6 aluminum is 6061 aluminum in the T6 temper To achieve this temper, the metal is solution heattreated and artificially aged until it meets standard mechanical property requirements The graph bars on the material properties cards below compare 6061T6 aluminum to 6000series alloys (top), all aluminum alloys (middle), and the entire database (bottom)Nonferrous Metal Composition Notes Aluminum content reported is calculated as remainder Composition information provided by the Aluminum Association and is not for designThe 6061 T6 aluminum tread plate has the highest corrosion resistance of all the aluminums that have been heat treated It is an alloy that has been formed with silicon and magnesium It has a lower strength than other comparable aluminums, but is still widely used

Mechanical Properties Of The Aluminum 6061 T6 Alloy Samples Download Table

Http Www Allianceorg Com Pdfs Alumext 6061t6 Pdf

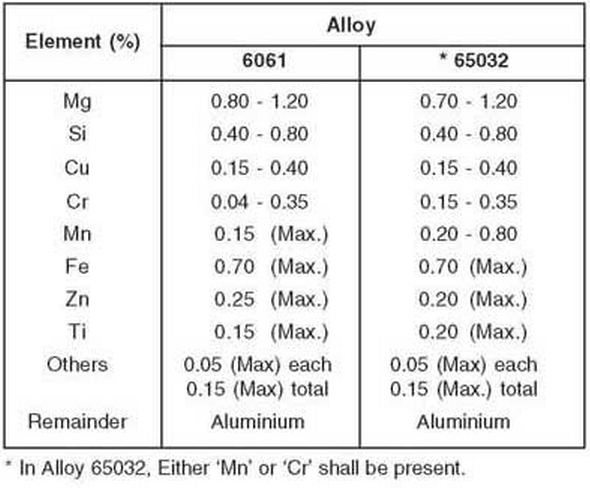

Can be molded into large, thin6061 Aluminum Alloy Properties General Characteristics Characteristic Appraisal Strength Medium to High Corrosion Resistance Good Weldability & Brazability Good Workability Good Machinability Good Chemical Composition Element Minimum % Maximum % Magnesium 08 12 Silicon 04 08 Iron No Min 07 Copper 015 04 Manganese No Min 015May 24, · Mechanical Properties Aluminium 6061T6 mechanical properties are listed in the following tables including yield strength (yield stress), ultimate tensile strength, shear strength, modulus of elasticity, young's modulus, etc

6061 T6 Aluminium Tubing Sasa Alloy Co Ltd

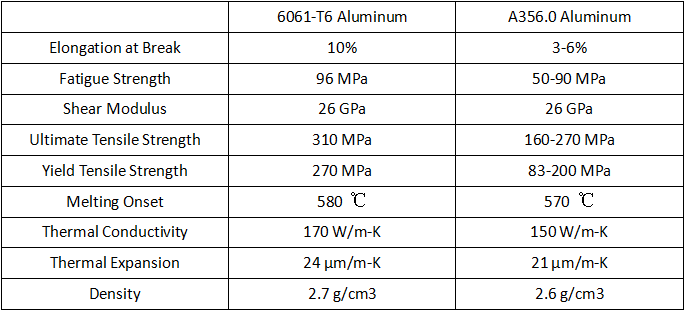

What Is A356 Aluminum A356 Aluminum Composition Properties Uses A356 Aluminum Vs 6061

Jun 01, 11 · understand that 6061T6 or 6063T5 can be used and want to know which would be better for our application There is a basic trade off between strength and corrosion resistance with the two alloys you've mentioned While 6063T5 gets an A rating for general corrosion resistance, 6061T6 gets a B The test isJul 03, 21 · This article will compare 6061 aluminum alloy and 7075 aluminum alloy, two common aluminum types that are widely used in industry (for more information, feel free to visit our articles all about 6061 and 7075 aluminum alloys, respectively) The differences in properties, strengths, and uses will investigated, so as to show where each of theseAluminum alloy 6061 t6 properties 6061 represents the alloy composition of the aluminum plate, and t6 is the heat treatment temper of the aluminum plate, which determines the mechanical properties of the aluminum plate t6 temper is suitable for products that no longer undergo cold working after solution heat treatment (can be straightened and leveled, but does not affect the

China High Quality For Beam 6061 T6 Aluminum I Beam With Ams Qq A 0 Standard For Construction Structure Sampmax Manufacturer And Supplier Sampmax

Material Properties Of 6061 T6 Aluminum Alloy Download Table

The last two digits in the 1xxx group correspond with the two digits after the decimal which indicate the minimum aluminum content For example the aluminum content of 1060 is 9960% minimum, 1100 is 9900% minimum, 1350 is 9950% minimum and so onSep 21, 17 · What Are The Specific Properties Of 24 And 6061 Aluminum?6061T6 Aluminum Properties Sapa Group 6061T6 aluminum properties include its structural strength and toughness 6061 T6 aluminum is commonly used in aircraft construction Contact Sapa Extrusi Chat Now Send Inquiry;

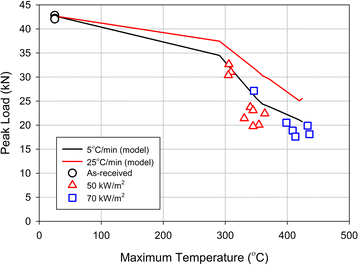

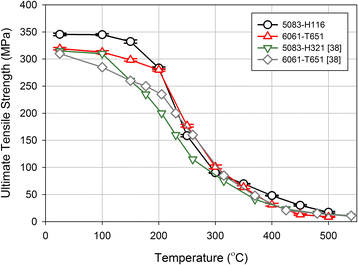

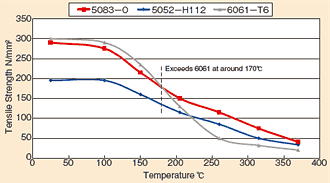

Overview Of Aluminum Alloy Mechanical Properties During And After Fires Fire Science Reviews Full Text

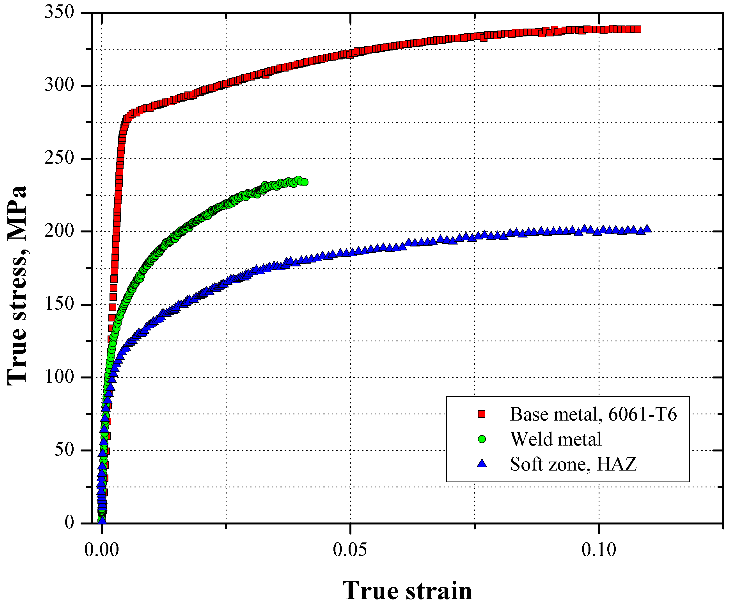

Mechanical Behavior Of Precipitation Hardened Aluminum Alloys Welds Intechopen

Properties –40% lighter than steel and % lighter than aluminum on a likeforlike strength ratio –Good damping qualities, absorbing noise and vibration –Low density means easier, faster machining of components –High thermal conductivity and good EMI shielding –Ductile, with ideal casting properties;6061T6 aluminum properties include its structural strength and toughness 6061 T6 aluminum is commonly used in aircraft constructionAluminium 6061 T6 Round Bar is made up of an aluminum alloy that is often used for their oxidation resistant properties and high heat capacities Navstar Steel is a leading supplier and manufacturer of the Aluminium 6061 T6 Round Bar and other types The material is composed of aluminum, chromium, titanium, magnesium, manganese, zinc, copper

6061 T6 Material Properties Lirtl Com

Journals Sagepub Com Doi Pdf 10 1177

Apr 01, 19 · fatigue properties of the 6061T6 aluminum alloy describes the fatigue life of the alloy, which is significantly affected by strain amplitude, rate, and frequency Therefore, the purpose of theAug 13, 19 · For example, 7075 exhibits very high strengthtoweight ratio In fact, 7075 provides the greatest strength available in aluminum bar It is widely used in aircraft applications where light weight plus strength are required, not to mention a high exposure to heat 6061 Aluminum Sheet 6061 T6 is one of the most common materials in the world6061T6 Aluminum Tube, 3/4" OD X 01" Wall x 12 FT, Mill Alcoa WWT700/6, QQ00/8*, MILT7081 6061T4 Flat Bar 6061 Aluminum Material Properties Aluminum 6061 is probably the most commonly available, heat treatable aluminum alloy Applications Aluminum 6061 is commonly used in the manufacture of heavyduty structures requiring

Material Properties Of Aluminum Alloy 6061 T6 Alumina And Steel Download Table

Journals Sagepub Com Doi Pdf 10 1177

May 30, · Both 6061O aluminum and 6061T6 aluminum are variants of the same material They share alloy composition and many physical properties, but develop different mechanical properties as a result of different processing For each property being compared, the top bar is 6061O aluminum and the bottom bar is 6061T6 aluminumMaterial Properties of 6061T4 and 6061T6 Aluminum Generally, 6061 aluminum is solution heat treated, then aged T4 temper aluminum is naturally aged, and T6 temper aluminum is artificially aged for maximum strength Physical Properties of 6061 Aluminum84 rows · 95 95 AA;

The Use Of Aluminum In Construction Eurocode 9 Part 1 Aluminium Guide Com

Physical Properties Of 6061 T4 Aluminum Download Table

Aug 01, · 6061 t6511 aluminum properties Although the strength of 6061 t6511 aluminum aluminum alloy cannot be compared with 2xxx series or 7xxx series, 6061T651 aluminum alloy has many characteristics of magnesium and silicon alloys, which have good processing properties, excellent welding characteristics and electroplating properties, and good corrosion resistance6000 Series Aluminum Alloy Material Notes General 6061 characteristics and uses Excellent joining characteristics, good acceptance of applied coatings Combines relatively high strength, good workability, and high resistance to corrosion;Nov 13, · 6061 T6 Extrusions Aluminium alloy 6061 is a medium to high strength heattreatable alloy with a strength higher than 6005A It has very good corrosion resistance and very good weldability although reduced strength in the weld zone It has medium fatigue strength

Magnesium Alloy Plate Sheet Aluminum 6061 T6 Prices Per Kg

Table 2 From Fatigue Crack Growth In Friction Stir Welds Of 60 T6 And 6061 T6 Aluminium Alloys A Comparison Semantic Scholar

6061T6 American Standard I Beam Aluminum Beam American Standard I Beam (S Shape) has been developed to show basic dimensions and sectional properties of American standard beam (S shape) S shapes have relatively narrow flanges The designation of the S shape gives information about the width and weight per unit lengthAluminum 6061T6 is the one of the most common types of aluminum metals used in the industrial world today With its high strengthtoweight ratio and excellent machinability, it is perfect for applications in aerospace, transportation equipment and construction materials manufacturing Aluminum 6061T6 is generally heat treated and2 days ago · The nominal composition of type 6061 aluminum is 979% Al, 06% Si, 10%Mg, 02%Cr, and 028% Cu The density of 6061 aluminum alloy is 27 g/cm 3 ( lb/in 3) 6061 aluminum alloy is heat treatable, easily formed, weldable, and is good at resisting corrosion

Strategies For Bending 6061 T6 Aluminum

When And Why To Use Aluminum 6061 Ryerson

There are many aluminum base materials that can be welded successfully with any number of different filler alloys The base alloy referenced in the above question, 6061T6 for instance, is commonly welded with at least four totally different filler alloys and

6061 Aluminum Forging

Dl Asminternational Org Handbooks Book Chapter Pdf A Pdf

Relationship Between Mechanical Properties And Microstructural Response Of 6061 T6 Aluminum Alloy Impacted At Elevated Temperatures Sciencedirect

Aluminium Alloys And Production

Mechanical Properties Of Aged Aluminum 6061 T6 Callister Jr 07 Download Table

Literature Mechanical Properties Of Aluminium 6061 T6 Alloy 18 Download Table

A Unidirectional Im 9 Carbon Fiber Hexply 8551 7 Chegg Com

Physical Properties Of The Aluminum Alloy 6061 T6 23 Download Table

Mechanical Properties And Dislocation Substructure Of 6061 T6 Aluminum Alloy Impacted At Cryogenic Temperatures Semantic Scholar

Material Properties For Aluminum 6061 T6 27 Download Table

Fatigue Properties Of 6061 T6 Aluminum Alloy Butt Joints Processed By Vacuum Brazing And Tungsten Inert Gas Welding Topic Of Research Paper In Mechanical Engineering Download Scholarly Article Pdf And Read For

Aluminum Alloy Properties And 6061 6063 Price Per Kg In India

1

Http Www Aluminum Org Sites Default Files Tech Q A From Aluminum Now 11 06 01 Pdf

Iopscience Iop Org Article 10 10 1757 9x 310 1 0127 Pdf

Duramold 2 Vs 6061 A Comparison Clinton Aluminum

The Use Of Aluminum In Construction Eurocode 9 Part 1 Aluminium Guide Com

A Study Of The Quench Sensitivity Of 6061 T6 And 6069 T6 Aluminum Alloys

6061 T6 Aluminium Supplier In China Chal

Aluminum Alloy Sheet 6061 T6 0x250x3 Mm Shopee Malaysia

Aluminio 6061 T6 6061 T651 Ultimate Tensile Strength Strength Of Materials

Mechanical Properties Of Aluminum 6061 T6 Download Table

Overview Of Aluminum Alloy Mechanical Properties During And After Fires Fire Science Reviews Full Text

Difference Of 6061 T6 6063 T5 Sunshield Aluminum Structures

Pdf Rotating Bending Fatigue Tests For Aluminum Alloy 6061 T6 Close To Elastic Limit And With Artificial Pitting Holes Semantic Scholar

Get Answer Repeat Problem 3 24 Except For 6061 T6 Aluminum Problem 3 24 Transtutors

Solved You Are Manufacturing A Frame For A Vehicle Out Of Chegg Com

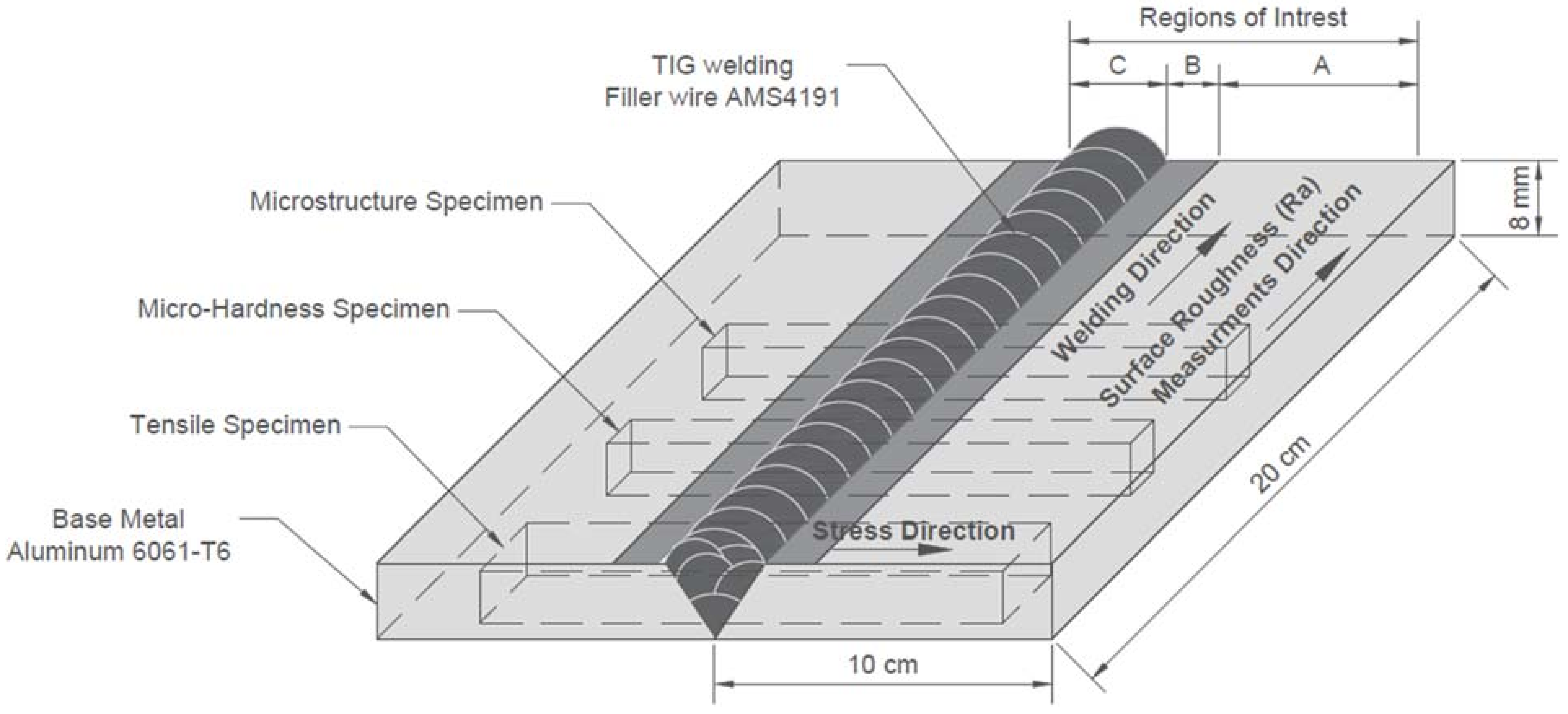

Materials Free Full Text Evaluation Of Surface Roughness By Image Processing Of A Shot Peened Tig Welded Aluminum 6061 T6 Alloy An Experimental Case Study Html

Material Properties Of 6061 T6 Aluminum Alloy Download Table

6061 T6 Aluminum Properties

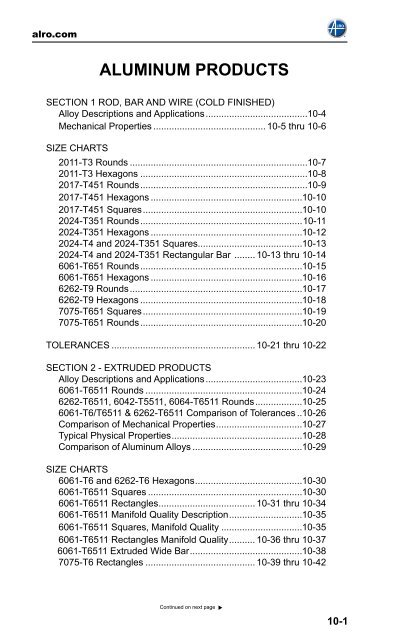

Aluminum Products

Digitalcommons Calpoly Edu Cgi Viewcontent Cgi Article 1122 Context Matesp

Table 3 From Comparison Of Impact Duration Between Experiment And Theory From Charpy Impact Test Semantic Scholar

High Precision Aluminum Plate Kobe Steel Ltd

Aluminium Alloy 6061 Aluminium Guide Com

6061 T6 Aluminium The Ultimate Guide Engineeringclicks

Stress Strain Properties Of Artificially Aged 6061 Al Alloy Experiments And Modeling Springerlink

Guide To 6061 Aluminum Properties Types Uses Aluminum 6061 Vs 6063 7075 And 24 Machined Parts At Best Price In China

Averaged Strain Energy Density Criterion To Predict Ductile Failure Of U Notched Al 6061 T6 Plates Under Mixed Mode Loading Sciencedirect

1

Fatigue Limit Investigation Of 6061 T6 Aluminum Alloy In Giga Cycle Regime Sciencedirect

Literature Mechanical Properties Of Aluminium 6061 T6 Alloy 18 Download Table

Aluminum 6061 T6 First Wall Material Properties Download Table

Mechanical Behavior Of Precipitation Hardened Aluminum Alloys Welds Intechopen

Strategies For Bending 6061 T6 Aluminum

6061 Aluminum Get To Know Its Properties And Uses Gabrian

6061 Aluminium Alloy Wikipedia

Al 6061 T6 Properties Matweb

Al 6061 T6 Aluminum Alloy Properties Density Tensile Yield Strength Thermal Conductivity Modulus Of Elasticity Welding

Local Mechanical Properties Of The 6061 T6 Aluminium Weld Using Micro Traction And Instrumented Indentation Sciencedirect

Pdf Microstructure And Properties Of 6061 Aluminum Alloy Brazing Joint With Al Si Zn Filler Metal Semantic Scholar

Pdf Effect Of Hardness Test On Precipitation Hardening Aluminium Alloy 6061 T6 Semantic Scholar

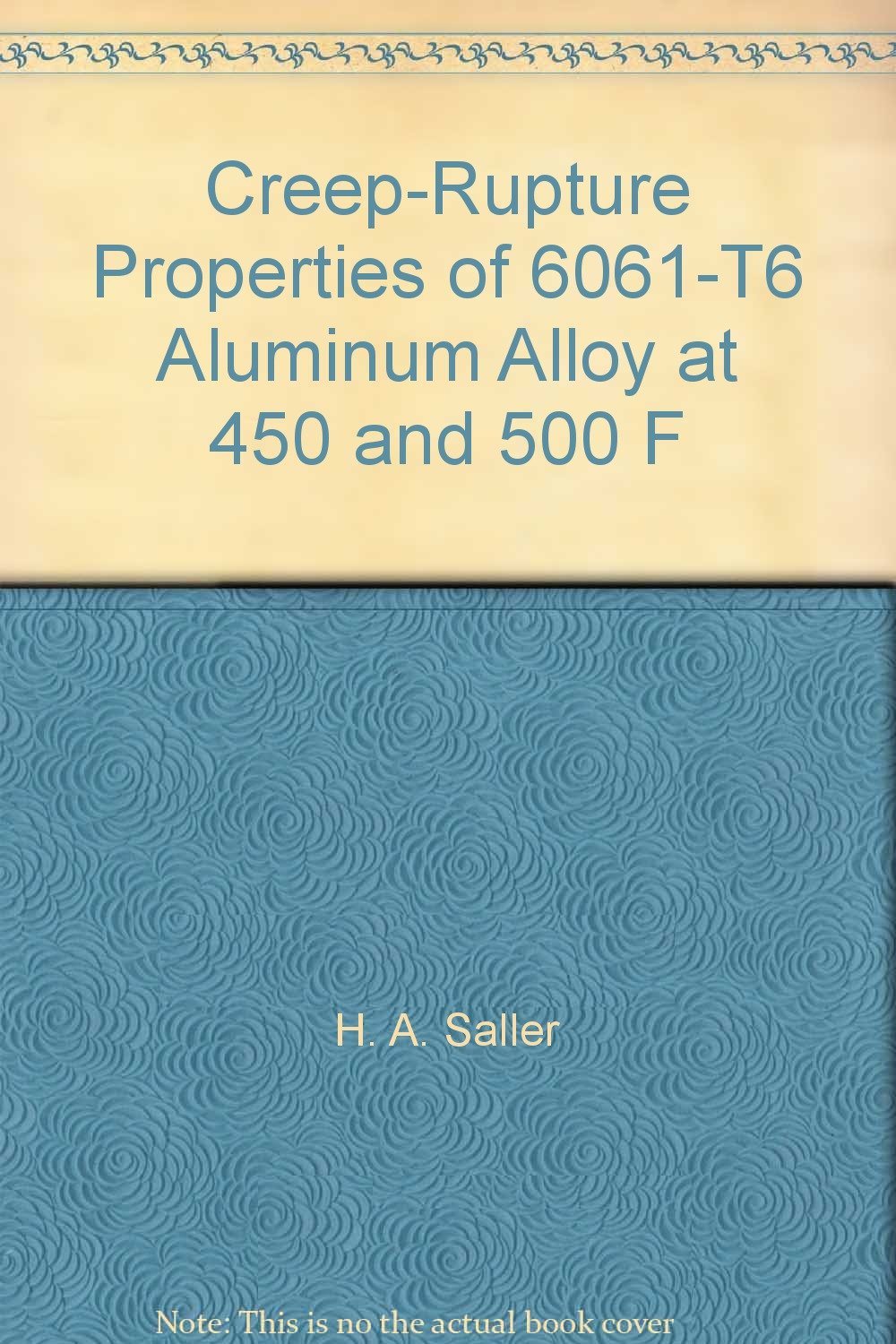

Creep Rupture Properties Of 6061 T6 Aluminum Alloy At 450 And 500 F H A Saller Amazon Com Books

Aluminum 6061 T6 Uns Nist

1

Al 6061 T6 Material Properties Download Table

Q Tbn And9gcqm Axy Lzszttk31caikxplub0bsgndlwbgqxqk0aiqzldjx0b Usqp Cau

Ppt 6061 T6 Aluminum Powerpoint Presentation Free Download Id

Aluminum 6061 T6 Uns Nist

Material Properties Of Al 6061 T6 And Cu Download Table

Investigation Of Post Weld Heat Treatment T6 And Welding Orientation On The Strength Of Tig Welded Al6061

Mechanical Properties And Dislocation Substructure Of 6061 T6 Aluminum Alloy Impacted At Cryogenic Temperatures Semantic Scholar

Overview Of Aluminum Alloy Mechanical Properties During And After Fires Fire Science Reviews Full Text

Properties Of Aluminum 6061 T6 Download Table

Aluminium Aluminum 6061 Alloy Uns 6061

Aluminium Alloy 6061 Aluminium Guide Com

Aluminium Alloys And Production

6061 T1 T6 Aluminum Alloy Grade Sheet Plate Coil 6061 T1 T2 T3 T4 T6

Material Properties Of Aluminum Alloys 6061 T6 Download Table

6061 T6 Aluminum Sheet Price Per Kg Manufacturer And Supplier China Properties Yiwanhong

Al 6061 Properties Matweb

Yield Strength In Exhaust Tubing Aluminum Vs Stainless Steel Burns Stainless

High Precision Aluminum Plate Kobe Steel Ltd

Press Brake Bending Applying The Percent Rule To 6061 Aluminum

6061 Aluminium Alloy Wikipedia

6061 T6 Aluminium The Ultimate Guide Engineeringclicks

9th Australasian Congress On Applied Mechanics Acam9 Ppt Download

When And Why To Use Aluminum 5052 Ryerson

コメント

コメントを投稿